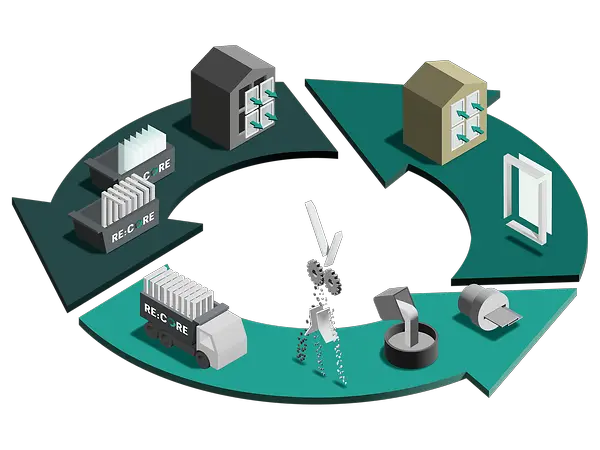

RE:CORE services – Efficient aluminium recycling for industry and the environment

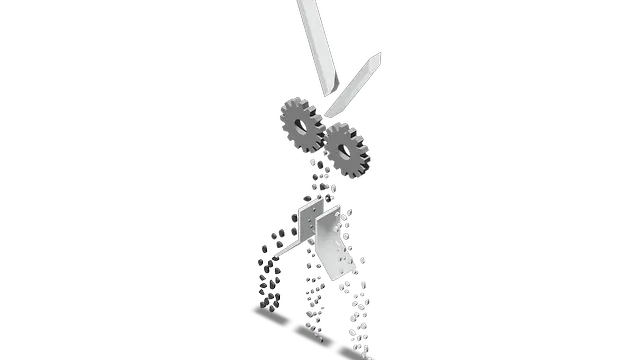

RE:CORE offers a comprehensive service for the recycling of building components. From the selection of the right containers and the coordination of the container logistics on the building site through to remuneration for the aluminium scrap and issue of the recycling certificates.